Project Dashboard: Venice Residence

Feasibility Study: Prefabricated Concept < $2M

Revised Project Vision

This revised proposal directly addresses the client's new budgetary target of under $2 million by pivoting from a traditional, site-built construction method to a high-end prefabricated approach. The guiding vision remains the same: to create a serene, Japanese-inspired sanctuary that merges a sleek "girder and panel" aesthetic with natural warmth.

By leveraging off-site manufacturing for the home's structural components, we can significantly reduce on-site labor costs, shorten the construction timeline, and achieve a higher level of precision and quality control. This strategy allows us to preserve the ambitious design—including the central atrium and rooftop oasis—while making the project financially viable.

This updated dashboard outlines the adapted architectural concept using prefab systems, a revised cost analysis reflecting this new methodology, and an expanded directory of specialized professionals who can execute this vision.

Visualizing the Prefab Concept

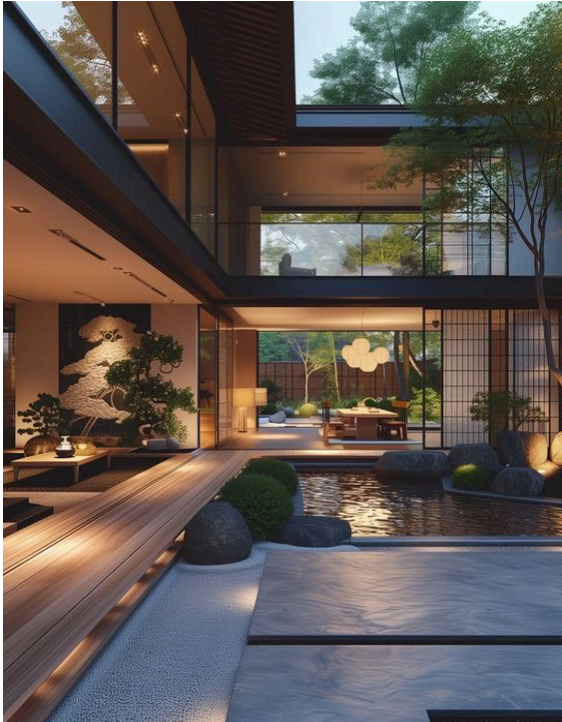

The following renderings illustrate how prefabricated systems can achieve the desired high-end aesthetic without compromise. The focus is on using panelized wall systems, Cross-Laminated Timber (CLT), and pre-finished modules to create a structure that is both beautiful and efficient to assemble.

Rendering 1: The Assembly Process

This rendering showcases the efficiency of the prefab method. A large, pre-clad wall panel, complete with an integrated window system and finished Shou Sugi Ban-style siding, is craned into place. This visual emphasizes that major components arrive on-site already finished, dramatically reducing on-site construction time and exposure to the elements. The precision of the panel alignment highlights the quality achievable with factory fabrication.

Rendering 2: The Seamless Interior

This interior view counters any notion of "prefab" looking generic. It depicts the main living space flowing into the central atrium, with floor-to-ceiling glass. The ceiling is made of exposed Cross-Laminated Timber (CLT) panels, lending a rich, natural warmth that complements the Japanese aesthetic. The clean lines and flawless junctions between structural elements showcase a level of craftsmanship that is a hallmark of high-end prefabrication.

Revised Cost Analysis for Prefab Construction

This budget targets a total project cost under $2 million. The primary savings are achieved by shifting a significant portion of labor from the high-cost LA market to an efficient factory environment and by shortening the overall construction timeline, which reduces financing costs.

| Phase | Estimated Cost | Notes |

|---|---|---|

| 1. Design, Engineering & Permitting | $185,000 | Includes architectural adaptation for prefab systems and structural engineering. |

| 2. Prefabrication Contract (Off-Site) | $850,000 | Core cost. Includes all structural panels/modules, windows, doors, and exterior cladding installed in-factory. |

| 3. Site Work & Foundation | $220,000 | Demolition, grading, and pouring a high-tolerance foundation required for prefab assembly. |

| 4. Module Transport & Crane Rental | $95,000 | Logistics of moving components from factory to site and crane services for assembly. |

| 5. On-Site Assembly & Finishes | $450,000 | Labor for module stitching, MEP connections, drywall, flooring, cabinetry, and fixtures. |

| 6. Landscaping & Site Systems | $150,000 | Includes atrium water feature, rooftop deck/spa, and basic landscaping. |

| Total Estimated Project Cost | $1,950,000 | Includes a 5% contingency within line items. |

Expanded Prefab Specialist Directory

To execute this vision, a team with specific expertise in high-end, modern prefabrication is essential. The following is a researched list of recommended firms and suppliers across the specified regions (CA, AZ, NV, OR, Northern Mexico).